PM313车轮底盘冷刨床

切割系统

- 铣削宽度

- 51.2in

- 最大铣削深度

- 13in

- 转子速度

- 97 / 109 / 121 RPM

- 位数

- 111

动力传动系

- 额定功率

- 336.6HP

- 引擎

- C9.3

- 最大行驶速度

- 4.7英里/小时

- 最大铣削速度

- 108英尺/分钟

权重

- 整机重量

- 47115lb

- 运输重量

- 43561lb

维

- 操作长度-输送机向上

- 36.45ft

- 操作宽度

- 8.33ft

- 高度-天篷

- 12.3ft

- 货车最大清关

- 15.42ft

- 最小右切割半径

- 6.56ft

- 最小左切割半径

- 13.88ft

- 输送机摇摆

- 距中心60度

- 运输长度

- 30.58ft

- 运输宽度

- 8.33磅/

- 交通高度

- 9.84ft

服务补充容量

- 液压油箱

- 15.6加(美国)

- 冷却系统

- 16.4加(美国)

- 喷水系统柜

- 332.9加(美国)

- 柴油机排气液(DEF)油箱

- 5.8加(美国)

- 机油

- 7.9加(美国)

- 油箱

- 158.5加(美国)

高效的性能

- 猫®C9.3 .发动机符合地区排放标准

- Smooth and efficient operation with Automatic Idle Control and multiple rotor speeds optimize output and demand on the engine

- High capacity cooling system keeps engine at ideal temperatures for optimal fuel efficiency and lower emissions

- Automatic load sensing on the rotor adjusts milling speed to prevent stalls and optimize production

机动性和控制

- Robust propel system features dual displacement planetary motors at each leg post, 利用交叉驱动模式,在直线切割额外的牵引力

- Automatic traction control maintains consistent speed in the most challenging applications

- Articulating right rear leg maximizes stability and traction in demanding cuts while enhancing flush cutting capability when needed

- Optional ballast weight kit available to increase productivity in specific applications

- Wheel or track undercarriage options offer a balance of traction, speed and maneuverability

- Reliable track undercarriage option leverages proven designs from 猫 dozers and an automatic tensioning system to ensure consistent performance and longer track life

- 能够在运行期间在转子转速之间进行电子切换

舒适的工作环境

- 操作舒适的标准悬挂座椅, 调节右臂控制台和直观, 符合人体工程学的控制

- 滑动操作站延伸至215毫米(8.5英寸),以提高切割边缘的能见度

- 白天或晚上在背光键盘和光线充足的工作区域工作

- 触摸屏显示提供对仪表集群的访问, 操作信息, 远程摄像机馈送, 机器控制和诊断

- Optional remote cameras enhance visibility to the cutting edges, conveyor, and rear of the machine

- Cut closer to obstacles on the right side using an optional remote camera above the cutter box with an adjustable on-screen guidance line

- 可选的挡风玻璃可以增加舒适度

- Maximize dust removal from the working areas with the optional dust abatement system

耐用切割系统

- 转子驱动系统采用重型干式离合器, 双级皮带传动,自动张紧皮带,防止打滑

- 增强切割室提供增强的耐用性

- Hardened full length side plate skis and anti-slab shoes reduce wear and maintenance

提高精度与集成猫技术

- 实现准确的, repeatable and automatic cutting precision with the integrated 猫 GRADE with Grade and Slope system

- The optional grade control box can be positioned in the operator station or on the back of the machine to enable interaction with the grade system from the ground level

- 从任何控制箱获得坡度和坡度的完全控制

- Seamlessly switch between multiple grade sensors for uninterrupted accuracy during milling

- Adjust the speed at which the rotor drops into the cut for optimal machine control

- Set and automate transitions in/out of cuts and save settings for future jobs

- Clear obstacles in the cutting path with ease using the obstacle jump feature

- 增强全3D铣削操作(需要额外的硬件)

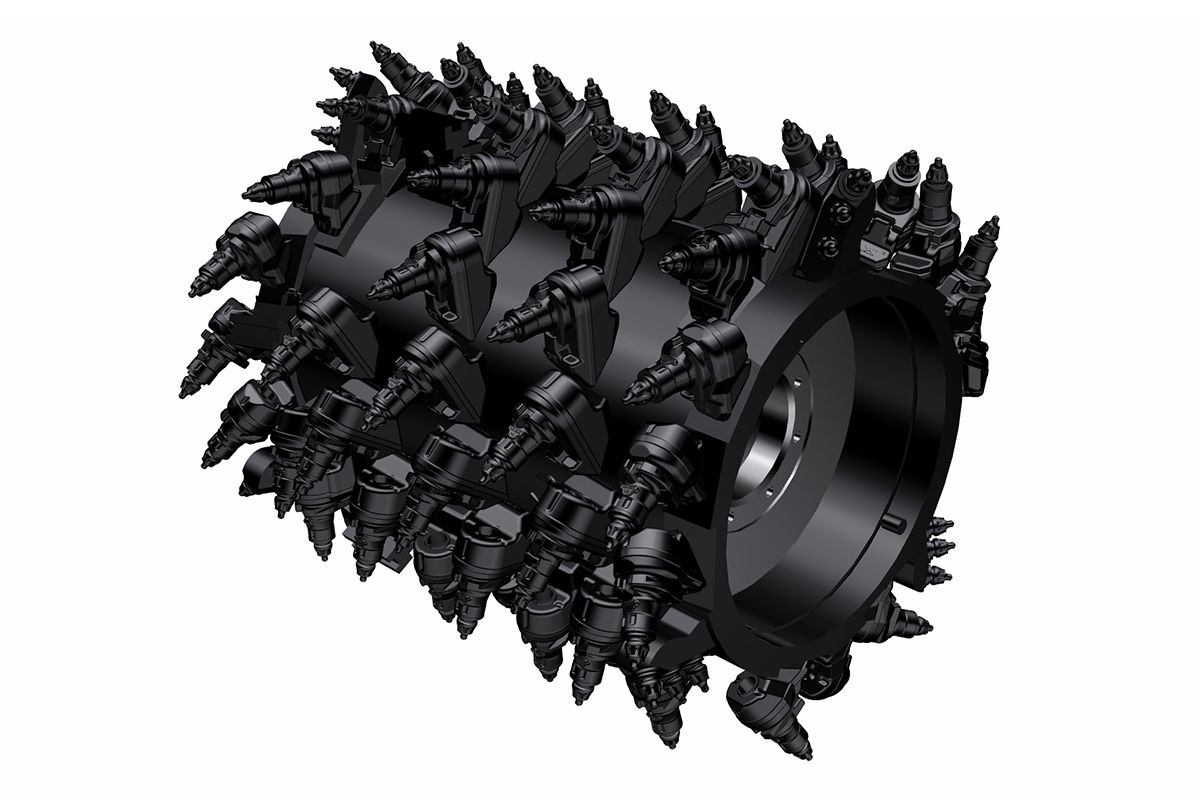

系统K转子

- 猫 System K rotors feature efficient material flow with an excellent cutting pattern for numerous applications

- A tapered dual-retention design secures toolholders in place without a retaining pin, 螺栓或固定螺钉, speeding up replacement and eliminating the need for fasteners or torqueing

- Reversible paddles and high strength alloys reduce wear and abrasion to extend rotor life

- Optional diamond bits can extend replacement intervals up to 80 times longer than conventional carbide bits

简化服务

- Maintenance is easier with large service doors for access to critical components

- Maintenance-free track components and easy to replace track pads lower service costs

- Standard ground-level controls and an optional hydraulically-operated rotor turning device simplify bit removal and replacement

- Operate select machine functions during maintenance and service with the accessory drive system

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, 耐磨尼龙编织,澳门新葡京博彩寿命更长

- 延长液压油澳门新葡京博彩间隔:3000小时不采样, 6000小时带油样

- 澳门新葡京博彩猫 Product Link™远程信息处理服务跟踪定期维护

- Electronic Control Modules (ECMs) monitor machine systems to alert the operator of performance issues and can be paired with Product Link options to enable additional remote services with your local 猫 dealer

- Multi-piece, 墨盒式发动机滤清器是环保的, 减少浪费,降低更换成本

- 方便的零件供应, dealer locations and service repair kits simplify ordering of high wear components